Materflow Oy Expands Its Services: FDM Printing Joins the Offering

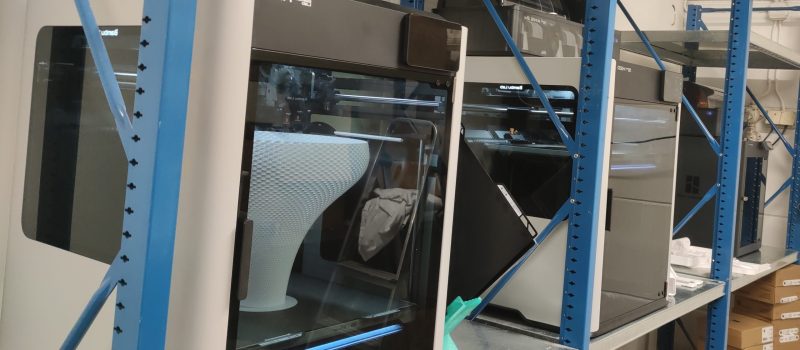

Materflow is introducing FDM 3D printing technology as part of its manufacturing services. This new printing service provides our customers with a cost-effective and seamless way to move directly from prototypes to professional series production of end products.

By continuously developing our operations, we ensure that our customers always have access to modern technologies and services. We have now launched a controlled pilot phase in which FDM printing (Fused Deposition Modeling) is integrated into our daily production.

FDM printing is a 3D printing technology based on the extrusion of thermoplastic filament. Another technology we use is SLS (Selective Laser Sintering), which utilizes a laser to fuse plastic powder layer by layer. FDM is one of the most widely used 3D printing methods in the world and is commonly applied by both hobbyists and professionals from early prototypes to finished end products.

FDM Creates a Bridge from Prototype to Finished End Product

Many of our customers already use desktop-level FDM printers. These are excellent tools in the early stages of product development: the first prototype can be produced quickly in-house and its basic functionality tested immediately. Iterations are easy when the printer is located on-site.

But what happens after the prototype has been proven functional and approved for further development?

Until now, Materflow has offered SLS and metal printing as the next step. However, we have identified a clear need: customers often want to continue using the same technology with which the prototype has already been validated, while requiring the enhanced repeatability and material properties necessary for end-use applications.

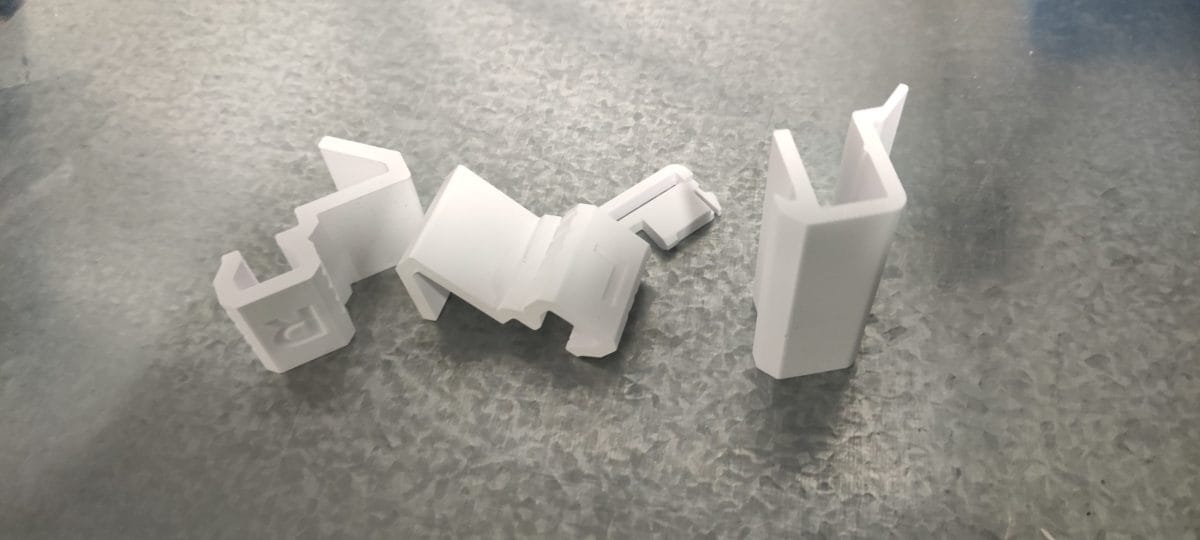

From Prototype to Series Production with Professional-Grade FDM Printing

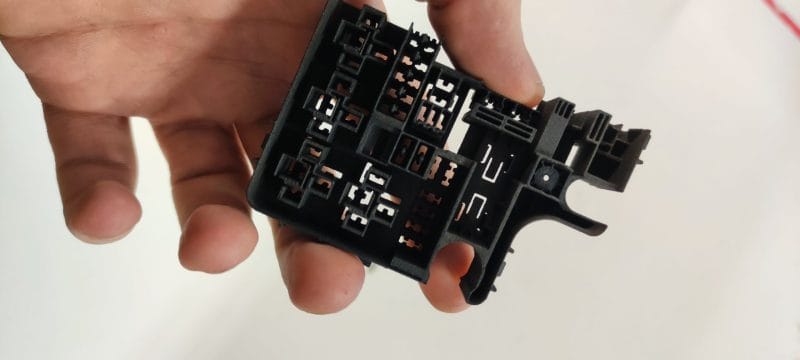

When a customer has produced and validated a prototype using FDM technology, production can continue at a higher capacity together with Materflow.

High-performance, professional-grade FDM printers suitable for series production enable the manufacturing of high-quality parts using a familiar technology. This means our customers do not need to worry about the potential impact of switching printing technologies on part design or dimensions when transitioning to final production.

What Is FDM Printing and How Does It Work?

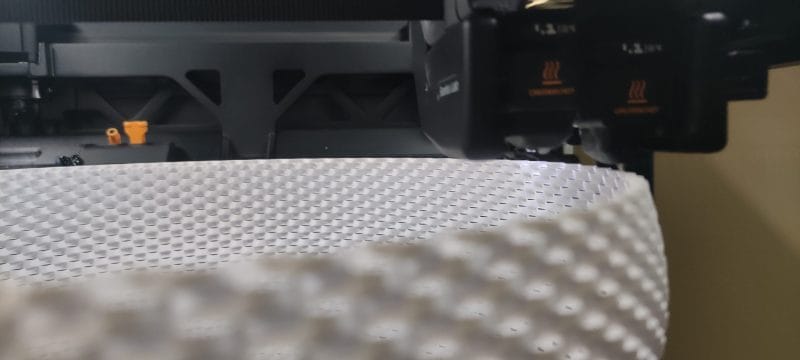

FDM is one of the most widely used 3D printing methods globally. It is based on melting thermoplastic filament and extruding it layer by layer through a nozzle. The manufacturing process is fast, produces mechanically durable parts, and is ideally suited for technical materials.

FDM or SLS?

Both FDM and SLS are suitable for a variety of applications. Materflow’s experts are happy to assist in choosing the most appropriate printing technology.

When Is FDM the Right Choice?

FDM is often a good option when single parts or small series are needed. It is particularly effective when the geometry is clear and the need for support structures is minimal. Simple geometries can be printed relatively quickly with modest material consumption.

Choose FDM when:

- You are producing individual parts or small batches

- The parts have specific material requirements

- The part geometry is clear or simple

- The need for support structures is minimal

When Is SLS the Right Choice?

When Is SLS the Right Choice? SLS does not require separate support structures, giving designers full freedom of geometry. If you need hundreds of small parts at once, the geometry is more complex, or the part includes internal channels, SLS is often a more cost-effective and consistent surface-quality solution.

Choose SLS when:

- Larger production volumes are required

- Repeatable mechanical properties are essential

- The part geometry is sufficiently complex

Technical Material Selection for Demanding Applications

During the pilot phase, we have selected five key materials that meet modern requirements in technical manufacturing:

- PPS: Currently in testing, but one of the most interesting options for high flame-resistance requirements, such as those found in rail applications

- ABS: A versatile base material for mechanical parts, jigs, and fixtures

- PC (V-0): High-performance polycarbonate with V-0 flame rating

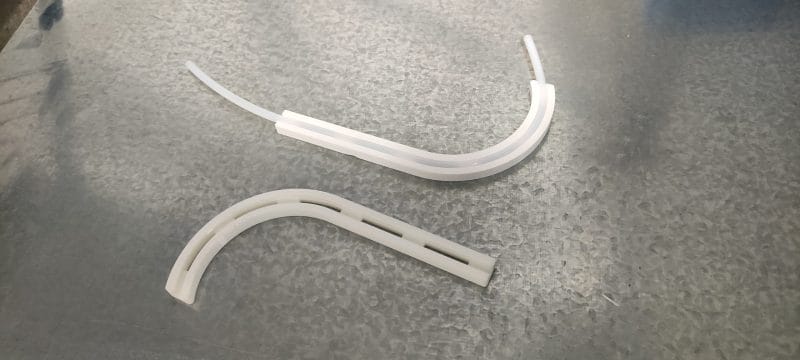

- PAHT-CF: Carbon fiber–reinforced engineering plastic offering exceptional stiffness and low weight; tensile strength in the XY direction exceeds 100 MPa

- TPU: Impact-resistant and shock-absorbing material capable of withstanding heavy mechanical stress; available in multiple hardness grades (Shore A & D)

High-Performance Materials

We will continue to expand our FDM material portfolio based on customer needs and material development.

Looking ahead, we are evaluating the broader adoption of PPS, which offers outstanding heat resistance and chemical durability for the most demanding industrial environments. Its suitability for flame-rated applications is among the best of all plastic materials. It complies with standards such as ISO 4589-2, ISO 5659-2, and AFNOR NF X 70.100-1-2.

Support Materials and Design Optimization

One of the most critical phases of FDM printing is part design. Support structures enable the production of more complex parts, but their removal requires additional work and affects surface quality.

If extensive support structures are needed, printing costs increase. Even more significant than labor costs is extended machine time and a higher rejection rate when complex supports interfere with surfaces or fail during printing.

Our experts help optimize part designs during the modeling phase to minimize the need for support material. This improves part quality and reduces manufacturing costs.

Quality Parameters and Process Control

FDM printing requires a controlled process influenced by many variables. We utilize hardware that allows for active process monitoring rather than simple automated printing.

Material Management and Moisture Control: Many technical materials, such as PAHT-CF, are highly sensitive to humidity. We ensure optimal drying and storage of materials under controlled industrial conditions to maintain mechanical integrity.

Mechanical Testing and Verification: When required, we perform tensile testing to verify the actual strength of parts in different print orientations. This is critical when FDM parts are used in load-bearing structures.

We offer our customers a controlled and transparent manufacturing process, so you know exactly what you are getting. Going forward, we will publish data on how infill density affects mechanical properties. Based on preliminary tests, 50–80% infill already delivers excellent performance.

Scaling Capacity According to Demand

We are launching the FDM service with a pilot phase to ensure quality and delivery reliability. While our initial capacity is limited, we are prepared to scale quickly as demand grows.

Fast response time: Increasing capacity based on demand is straightforward for us. However, growth is only possible once each material and process step has been thoroughly tested in-house. This allows us to guarantee technically robust results without compromise.

Why Choose Materflow’s Printing Services?

By choosing Materflow as your partner, you gain access to years of experience in industrial manufacturing.

- Expertise: Assistance in selecting the right method (FDM, SLS, or DMLS).

- Production Capacity: Scalable manufacturing immediately following a successful prototype.

- High-Performance Materials: We enable the use of technical polymers that require industrial-grade process control and high temperatures for successful application.

- Verified Production Quality: A controlled process with proven repeatability.

Contact Us and Take Your Project to the Finish Line

If you are currently developing a prototype using your own FDM printer and considering the next step toward end-product manufacturing, get in touch with us. We provide guidance on design and offer industrial-grade FDM printing services for final production.

Contact us and let’s find the best solution for your specific needs together.