Prototypes

PROTOTYPES: EXPLORE THE BENEFITS OF ADDITIVE TECHNOLOGY

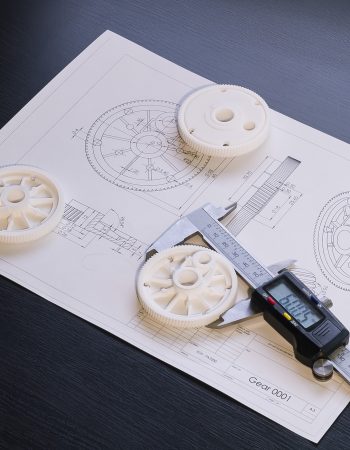

Discover how 3D printed prototypes can enhance your product development process by offering a more cost-effective and efficient approach. Traditional prototyping methods often come with high costs, which can be significantly reduced by utilizing 3D printing technology.

The absence of tooling or molding requirements means that your product can be printed directly from a digital design, allowing for adjustments as needed. This streamlined process not only makes prototyping more efficient than conventional methods, but it also enables multiple iterations at once to save time.

QUALITY PROTOTYPES DELIVERED THROUGH 3D PRINTING With modern 3D printing technology, the quality of your metal or plastic prototypes is comparable to those produced using traditional methods. Our 3D printers can effortlessly create ready-to-use parts with intricate geometries and complex shapes.

Once your prototype is complete, 3D technology facilitates a seamless transition to mass production. As your industrial printing partner, we’ll be there to support you throughout the entire process, from prototyping to serial production.

Curious about how 3D printed prototypes can benefit your business? Feel free to contact us to learn more and discuss how we can help you turn your ideas into reality!

PROTOTYPING

- Cost-effective and fast

- Quality on par with traditional methods.