Production &

Materials

Production &

Materials

We are grounded in R&D. Our innovations, tried-and-tested methods, and continuous co-op with equipment and material manufacturers ensures our industrial scale capabilities and tailored services for a variety of clients.

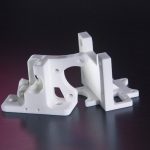

Plastics

PA 12 Grey

Dark grey nylon material for end-use products, spare parts and prototypes.

PA2200 (PA12)

Standard industry material for end-use products, spare parts and prototypes.

PA3200GF (PA12GF)

A glass reinforced variation of standard PA2200.

PA2210 FR – UL 94 V-0

A fire rated, halogen free nylon. FAR 25,853 tested and approved.

ROLASERIT® TPU

Multi-purpose thermoplastic polyurethane for applications requiring high flexibility.

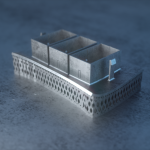

Metals

SS 15-5 PH

Good mechanical properties and corrosion resistance

Aluminium AlSi10Mg

Light weight and cost-friendly material, good mechanical properties.

Cobalt chrome

For demanding industrial environments and medical appliances.

SS 316L

Corrosion resistant versatile material for many uses and industries.

Tool steel

Strong, hard, and durable material for industrial applications and tooling.

Technology

FARSOON FLIGHT 403P

Next Generation Flight Technology (SLS)

2X EOS EOSINT P395

Plastic printer, Selective Laser Sintering (SLS) technology.

EOS EOSINT P380

Plastic printer, Selective Laser Sintering (SLS) technology.

SLM 280HL

Metal printer, Selective Laser Melting (SLM) technology.

CONCEPT LASER MLAB CUSING

Metal printer, Selective Laser Melting (SLM) technology.

EOS M270

Metal printer, Selective Laser Melting (SLM) technology.

Post processing

Machining equipments for plastics

- Shot peen blasting systems (manual and automated).

- Vibratory finishing for smoother surface quality. Object max size 300 mm, some geometry limitations.

- Dyeing systems. Black dyeing available on printers’ max printing size. Other colors with some geometry limitations. Objects approx 250 mm in size can be dyed in any color.

- Painting is subcontracted case-by-case basis

Machining equipments for metals

- Annealing ovens: for stress relieving, hardening and annealing.

- Machining equipment for post processing according to need: metal lathe (approx 120 mm, length approx 400 mm), triaxial cutter (approx 500×250 mm), band saw for removing printed parts from build platform.

- Finishing equipment: belt sanders, polishing tools, grinding tools etc.

Quality control

- Laser power measurement device Primes Cube M.

- Tensile strength measuring (Testometric, 50kN)

- Residual oxygen measurement device for observing gas circulation.

- Calipers (calibrated).

- Microscopy.

- 3D-scanning for quality verification.

- MFI measuring instruments for plastics.

- Kern analytical balance.

- Sub-contract laboratories: Muovipoli Ltd & LAB University of Applied Sciences

- SEM, additional tensile testing etc.

- Recording cameras in every printing machine.