3D Printing of Plastic Parts Is a Cost Issue for Barfix

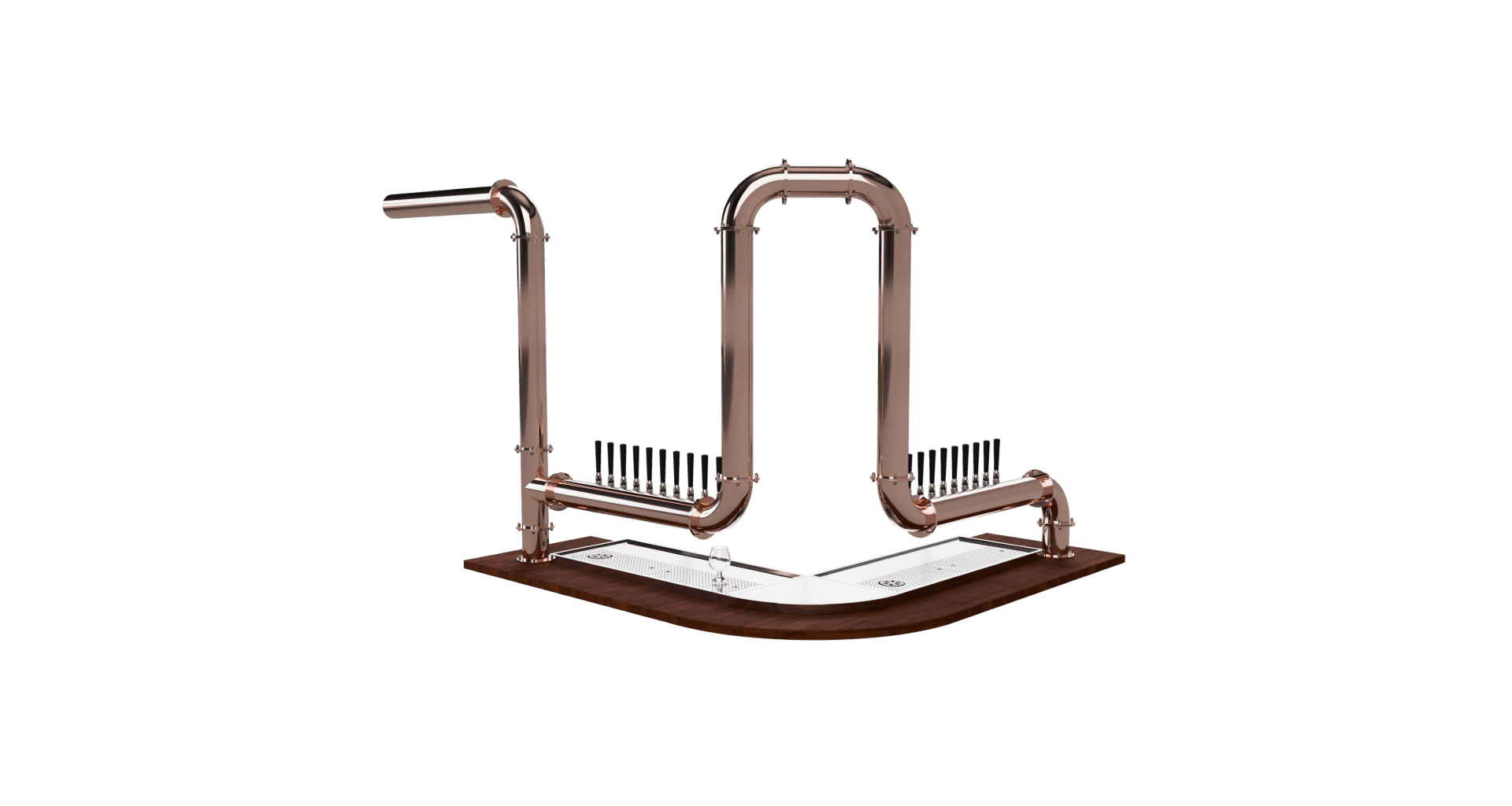

Barfix Oy is a company established in 1989 that manufactures beverage dispensing systems. The company’s products include, for example, beer taps for restaurants as well as dispensers for wine, water, or milk. Its clientele consists of restaurants, bars, and breweries. For restaurants, Barfix delivers complete systems that are designed individually for each space, whereas breweries receive the components needed in dispensing systems.

Barfix sources parts for its dispensing systems from several different suppliers, and 3D printing is also used as one of the solutions.

“Our collaboration with Materflow began in the fall of 2018,” says Barfix’s Mikko Myyryläinen.

“We had been considering 3D printing as a method for a long time and were waiting for the technology to mature.”

Less Risky Than Investing in a Mold

At Barfix, 3D printing has been used, among other reasons, for cost-related purposes. Many small plastic parts would be expensive and difficult to manufacture by machining or injection molding.

“For example, this kind of tap key would be very expensive if machined, or even more expensive if injection molded,” Myyryläinen says, showing a small key with several narrow projections extending in different directions.

“There’s very little mass here, meaning little plastic. It’s quite inexpensive to produce by printing.”

If that particular plastic part were manufactured using a traditional subtractive method, a lot of plastic material would go to waste. Certain types of plastic materials can be quite costly, so the waste material would be expensive.

Producing the mold required for injection molding, on the other hand, would be a major initial investment: in Barfix’s case, the first produced part would have cost €12,000. Since there is no precise information at the start of production about how large or small the quantities of each part will be in the future, it makes sense to minimize financial risk by choosing a manufacturing method that does not require a large upfront investment.

“Another example is the LED light shade used in the beer tower. It’s used in a beer tap that includes branding — for instance, the logo or name of a beer brand.”

According to Myyryläinen’s estimate, Barfix has so far produced about 1,500–2,000 of these shade components.

“In the long run, these might have been cheaper to produce by injection molding, but at the time we started making them, we didn’t know whether the quantities would reach that level or not. So this was a safe and easy choice in that sense.”

Read more about Materflow’s 3D printing service for plastic.

3D Modeling of Components Serves Two Purposes

Myyryläinen believes that 3D printing is already an everyday reality for many companies. For Barfix, it is one manufacturing method among others, and new parts are 3D printed as the need arises. The company’s readiness to utilize 3D printing is strongly supported by its existing expertise in 3D modeling.

“The decision to choose 3D printing as one of our manufacturing methods also stemmed from the software side: by that point, we had already been designing some of our own products using 3D modeling. Once you can directly export that model into a printable format, it’s kind of a no-brainer that the same model can also be used in production.”

Barfix’s goal is to 3D model every possible component in its dispensing systems. This serves two purposes: the design of the dispensing systems and the flexible 3D printing of components.

“In practice, the customer provides us with a model of the restaurant counter, and we insert our components into it to see how much space they take up, for example. In restaurants, space is always limited, and efficient use of it is an important factor.”

With 3D printing, Barfix can model and order exactly the parts needed at any given time quickly and smoothly. 3D printing also enables cost-effective ordering of small batches. Materflow’s location in Lahti allows for fast deliveries — sometimes Barfix staff even pick up the finished batch directly from Materflow’s premises.

At present, Barfix only prints plastic parts made of PA12 nylon, but for suitable projects, the best production method is always evaluated. Myyryläinen anticipates that in the future, Barfix will also explore 3D printing of metal parts as well as printing various seals made from rubber-like TPU plastic.