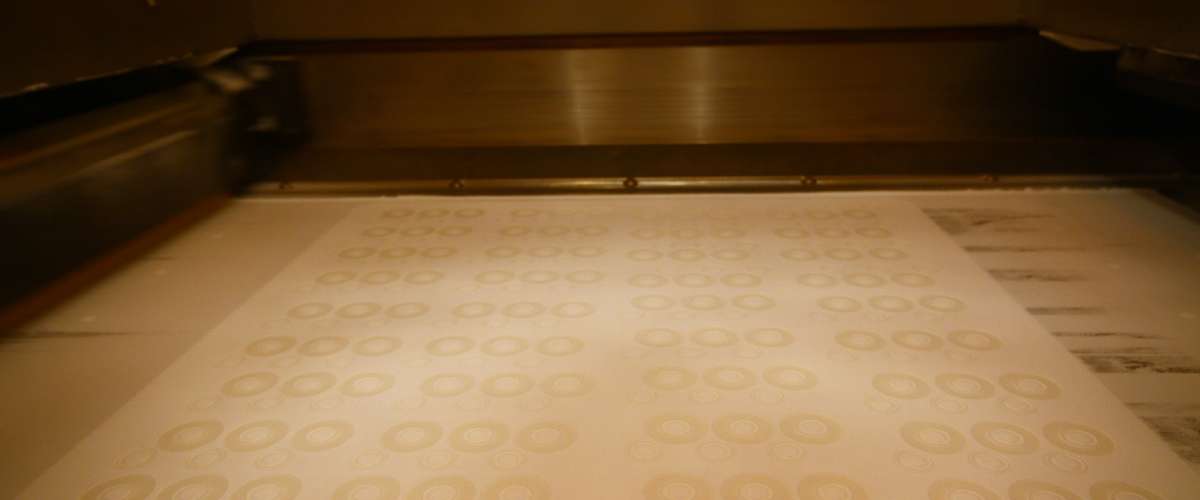

Build chamber of P395 Eosint

EOS Eosint P395

Plastic printer, Selective Laser Sintering (SLS) technique. Parts produced with SLS consist of layers of about 0.1-0.15 mm. In SLS Powder Bed Fusion the entire build platform is filled with an even layer of plastic powder. A high-powered laser fuses the desired form on to the powder, the print machine lowers the build platform according to the layer thickness, a new layer of powder is spread, and the laser fuses the form. This process is repeated until the parts are ready. The surrounding excess powder supports the structure. Laser sintering technology has no geometric constraints except for solid empty structures (e.g. a hollow sphere).

Read more:

> About Selective Laser Sintering

> Design Guidelines for Selective Laser Sintering

- 3D Printing Technology: Selective Laser Sintering

- Build Chamber Size: 340 mm x 340 mm x 620 mm

- Laser power: 70 W CO2 Laser

- Laser Spot size: Approx 600 μm

- Typical layer thickness: 0.12 mm

- Scanning Speed: Typically around 4-6 m/s depending on material

Read more:

> Technical Information, EOS P395

PA2200

PA12 -polyamide, white. Most commonly used basic material.

PA2210FR

PA12 based polyamide with with a halogen free, chemical flame retardant.

PA3200GF

PA12 based polyamide with glass beads